I. Introduction

With the rapid decline in the cost of photovoltaic energy storage systems and the increasing demand for new energy power, the investment feasibility of photovoltaic storage projects is getting higher and higher, so the enthusiasm for project investment is high. For photovoltaic energy storage projects at home and abroad, what project information should we obtain during preliminary project research? Among them, what information is best obtained through communication with the owner? What information is best investigated and clarified on your own? How to further logically complete the photovoltaic energy storage system configuration and core component selection after understanding the relevant project information is worthy of the attention of every installer, EPC or other engineering company.

II. Project survey, what to talk about with the project owner?

1. Residential solar battery projects

1) Electricity consumption and electricity prices

a) The annual electricity consumption of the site and the price of electricity;

b) If there is a time-of-use (TOU) electricity price mechanism at the project site, such as the British Economic Seven electricity price policy, then the subsequent system operation strategy settings can also be set to: in spring, summer, and autumn, the system operates to maximize self-use of photovoltaic; in winter, running under the system operation strategy of scheduled charging and discharging. Help households achieve the lowest electricity bills as much as possible.

2) Roof type and load-bearing assessment

a) What is the approximate area of the roof that can be mounted? What is the approximate slope of the roof?

b) Generally, household roofs include tiles, color steel tiles, etc. The hooks of the bracket systems used on tile roofs and color steel tile roofs are also different.

b) The age of the building, the approximate load-bearing and waterproofing assessment of the roof, and if possible, it is best to obtain the roof structure drawings.

2. Commercial and Industrial(C&I) Photovoltaic Projects

1) Electricity consumption and electricity prices

The annual electricity consumption of the site and the price of electricity;

2) Installable area and type of installation site

a) How large is the approximate area of the installation site?

b) What type of installation site is it, roof installation, solar carport or ground installation? If it is installed on the roof, is it a cement flat roof or a color steel tile roof? It would be a good idea to take some photos of the roof being installed.

The age of the building, the approximate load-bearing and waterproofing assessment of the roof, and if possible, it is best to obtain the roof structure drawings.

3) Transformer utilization rate at the installation site

Check the current usage of the power access transformer at the installation site. How much excess transformer capacity (kVA or kW) is available for solar low-voltage grid connection? The project cost of this low-voltage grid-connected system is lower. Otherwise, it is necessary to consider additional configuration of transformers for high-voltage grid connection, and the project cost and period will be slightly longer.

3. Commercial and Industrial(C&I) energy storage projects

1) Electricity consumption and electricity prices

The annual electricity consumption of the site and the price of electricity;

b) If there is a time-of-use (TOU) electricity price mechanism at the project site, figure out the peak and off-peak electricity prices and corresponding time periods, to evaluate the economic feasibility of energy storage system installation.

2) Retrofitting on existing PV system or integrating with new PV installation?

| Dyness DC-coupled PVESS | Sermatec AC-coupled ESS |

DC-coupling system vs AC-coupling system

Find out whether the site already has photovoltaic installations or whether a new photovoltaic system needs to be installed at the same time with energy storage to determine whether the optimal configuration of the system is a DC coupling solution or an AC coupling solution.

a) If photovoltaics has been installed and additional energy storage is added for system retrofitting, PCS (battery inverter) can be used to form an AC coupled photovoltaic energy storage system;

b) If it is a new installation of photovoltaic energy storage system, for small and medium-sized systems below 500kWh, it is recommended to prefer the DC coupling system. The system economy may be better and there is no need for joint debugging of communication protocols between the energy management system (EMS) and the photovoltaic inverter. For systems exceeding 500kWh, it is best to use high-power energy storage converters and photovoltaic inverters, so the AC coupling system should be more cost-effective. Moreover, when it comes to parallel control of multiple devices, the AC coupling architecture is relatively easier to implement and operate stably.

3) Transformer utilization rate at the installation site

Check the current usage of the power access transformer at the installation site. How much excess transformer capacity (kVA or kW) is available for energy storage low-voltage grid connection? The project cost of this low-voltage grid-connected system is lower. Otherwise, it is necessary to consider additional configuration of transformers for high-voltage grid connection, and the project cost and period will be slightly longer.

4) Is there a demand for off-grid power backup?

Introduce to the owner that the system can meet the demand for off-grid power backup by optionally equipping an automatic off-grid switching device (STS), but this will incur additional STS equipment costs, and ask whether there is indeed a need for off-grid power backup. If it does exist, the off-grid switching function should be considered when configuring the solution and selecting the equipment.

III. Project research, what else needs to be investigated by yourself?

In addition to chatting with the project owner to obtain the above information, the following relevant information about the project area can also be collected through desktop research and other methods.

1. Photovoltaic or energy storage projects

1) Climatic temperature

Most PV or battery inverters derate when the environment temperature is over 45 degrees. When the ambient temperature is higher than 45°C or lower than -20°C, special attention should be paid to selecting a battery system with a high-power air conditioner or battery preheating circuit, but this will reduce system efficiency and economy.

2) Altitude

Most PV or battery inverters (PCS) derate when the altitude exceeds 3000m; redundant design must be done when configuring system capacity.

3) Certification requirements for regional market entry

Product selection needs to consider regional market entry certification. Otherwise, if the selected equipment does not have entry certification for the area, it will be extremely difficult to accelerate the manufacturer's equipment certification with a project. This can lead to reselection and project schedule delays. For photovoltaic energy storage systems, they mainly include:

Regional market access safety regulations, etc., such as EU CE certification, etc.;

b) General grid connection regulations for inverters and converters and special requirements for regional grid connection. For example, the EU's EN50549, Germany's VDE AR-N 4105; the UK's G98/G99, Italy's CEI 0-21, etc; special requirements for power grids such as Austria's Tor, Poland's NC Rfg, the UK's ENA listing, etc.;

c) Safety and transportation certification of battery systems, such as:

- IEC62619 for battery system safety regulations

- UN38.3 for transportation and MSDS for export

2. Photovoltaic projects

If solar installation is involved, you also need to consider:

1) Local solar irritation

Solar irradiance is the power per unit area (surface power density) received from the Sun in the form of electromagnetic radiation in the wavelength range of the measuring instrument, it is crucial to the power generation of photovoltaic power stations.

2) Electricity selling price and electricity consumption price

Electricity price, which basically should include the electricity selling price and electricity consumption price. And cross-check it with the information provided by the project owner.

- Regarding electricity sales prices, for small and medium-sized 380V/400V low-voltage user-side projects, you need to know the local feed-in tariff (FiT); for large-scale high-voltage grid-connected projects, you need to know the approximate local PPA electricity price;

- Regarding the price of consuming electricity, it is mainly based on the type of project and the corresponding electricity price should be clear.

IV. What are the key points in project capacity configuration and equipment selection?

1. Project configuration calculation logic

1) Residential, C&I solar battery projects

For project scenarios that maximize self-consumption behind-the-meter such as residential or C&I solar battery, the required discharging power and system energy are estimated based on the rough load power and power consumption duration of peak demand; if the discharging power is within the allowable range of the discharge rate of the energy storage battery (generally ≤0.5C continuous charge and discharge), the charging power can be roughly estimated based on this. Considering the average solar irritation and rough energy demanded, it is feasible to calculate the rough PV system power, which should be compliable with the restricts of the installable area;

Deye Commercial Solar Battery

2) C&I energy storage behind-the-meter

For C&I energy storage project for Peak and off-peak arbitrage behind-the-meter, the charging and discharging power of the C&I ESS is generally estimated based on the peak/off-peak electricity price period as well as the corresponding duration. The energy of the C&I ESS is estimated by the peak demand area to be shaved. Finally, considering restricting factors such as project budget, installable area, continuous system charging & discharging rate etc., we can make appropriate corrections to get the final the system energy and power.

3) Medium or large-scale PV storage plants

For renewable penetration applications of medium and large-scale PV storage plants, based on the renewable generation and power to be absorbed, removing the part that can be absorbed by the grid, and the remaining energy and power can be roughly used to estimate the energy and power of the energy storage. And then based on the power demand during peak hours of the grid, the discharging power of energy storage can be roughly estimated. Finally, considering restricting factors such as project budget, installable area, system charging & discharging rate etc., we can make appropriate corrections to get the final the system energy and power.

2. PCS selection: how to choose between modular PCS vs centralized PCS?

For commercial, industrial and large-scale energy storage applications, the choice of modular PCS or centralized PCS for energy storage systems is currently affected by factors such as project area, project scale, application type, unit cost requirements, and installation site characteristics.

Compared with modular and string converters, the more parallel branches of a centralized converter, the worse the safety and the worse the temperature control consistency of the battery cells and the system. However, a single centralized converter has high power, and the number of equipment is smaller for the same project scale. Therefore, the dispatch response rate is fast and the accuracy is high, and the unit equipment cost is lower.

1) C&I grid-connected energy storage

For grid-connected C&I energy storage applications, modular PCS is currently widely used because of its flexible capacity configuration and ability to be installed dispersedly. Especially for overseas markets, modular PCS has been widely used because of factors such as certification and project capacity coverage.

2) C&I on-/off-grid energy storage

For commercial and industrial energy storage systems that require on-grid and off-grid switching, if the overall scale of the system is less than 500kW, modular PCS of about 100kW is currently mainly used; for systems exceeding 500kW, centralized PCS is recommended, or it is already based on basic AC-DC conversion The module is integrated into the PCS system.

3) Large-scale energy storage systems with grid-forming requirements

For large-scale energy storage systems that require grid-forming function, centralized PCS is generally used.

| SINY Modular PCS | Kstar 1.725MW Central PCS |

Modular PCS vs central PCS

3. Battery system selection: air-cooling vs. liquid-cooling, how to choose?

1) Residential ESS

For home storage systems, the battery system is usually an air-cooling system.

Bytewatt natural air-cooling residential ESS system

2) C&I ESS

For C&I BESS,

a) When using battery cells below 200Ah and the continuous discharge rate does not exceed 0.5C, air-cooled battery systems can be used.

b) When battery cells of 280Ah and above (280/ 300/ 306/ 314/ 315/ 325/ 345 Ah) are used, the current mainstream of battery systems is mainly liquid cooling, supplemented by forced air cooling.

|

|

Kstar forced-air cooling battery cabinet | Kstar liquid-cooling battery cabinet |

Air-cooling vs liquid-cooling

3) Large-scale ESS

`

Sermatec 5MWh liquid-cooling containerized BESS

For large-scale energy storage systems, when using existing mainstream production batteries of 280 /300 /306/ 314/315 / 325 / 345Ah, liquid cooling designs are currently the main ones, and the charge and discharge rate does not exceed 0.5C. Some systems have used larger capacity batteries of 500Ah+ (530/ 560/ 587/ 628/ 630/ 690/ 1130Ah). However, according to some manufacturers, although the lamination process has been used to replace the original winding process, the Some temperature characteristics, but currently 500Ah+ batteries are still recommended to be charged and discharged slowly, generally for long-term energy storage applications of 4 to 8 hours; a few leading manufacturers can continuously charge and discharge their large-capacity batteries at 0.5C.

500Ah+ large capacity battery cell for large energy storage

4. Selection of PV modules

1) Residential Solar Battery

a) To ensure flexibility in roof installation, home photovoltaic systems still mainly use small-sized photovoltaic modules of 400W~450W;

b) Markets such as the UK and Benelux seem to prefer all-black solar or BC solar modules, although all-black modules are 5 to 10W lower than ordinary modules of the same size, and BC modules are about 10% more expensive. However, there does not seem to be a particularly clear preference for this in the German-speaking area or other markets in Europe;

c) Benefiting from TopCon’s higher efficiency, N TopCon’s double-glass modules have gradually occupied the original market share of PERC modules. Since the back of double-glass modules is also encapsulated with glass, it has better sealing performance. Mainstream manufacturers have provided double-glass products with a 30-year performance warranty.

2) Commercial and industrial photovoltaic systems

a) Photovoltaic modules with a power of around 600W are the mainstream preferred modules in commercial and industrial photovoltaic projects;

b) Benefiting from TopCon’s higher efficiency, N TopCon’s double-glass modules have gradually occupied the original market share of PERC modules. Since the back of double-glass modules is also encapsulated with glass, it has better sealing performance. Mainstream manufacturers have provided double-glass products with a 30-year performance warranty.

3)Utility-scale PV plant

a) HJT modules has started its commercialization journey from ground PV as energy generation efficiency and low-temperature characteristics are more concerned in this field. 700W HJT modules from Risen has shown its efficiency advantages in utility-scale PV projects;

b) The size of PV module for utility-scale PV application has been even larger with the 210 large PV cells.

c) Based on project bankability assessment, Bloomberg Tier 1 rankings still have a key influence on module selection for large-scale photovoltaic projects.

5. Selection on Mounting Structures

1) Residential Solar Battery

b) Generally, household roofs include tiles, color steel tiles, etc. The hooks of the bracket systems used on tile roofs and color steel tile roofs are also different.

| Mounting system & hooks for tile roof installation | mounting system & hooks for color steel roof installation |

Mounting structures for tile roofs and colored steel tiles roofs

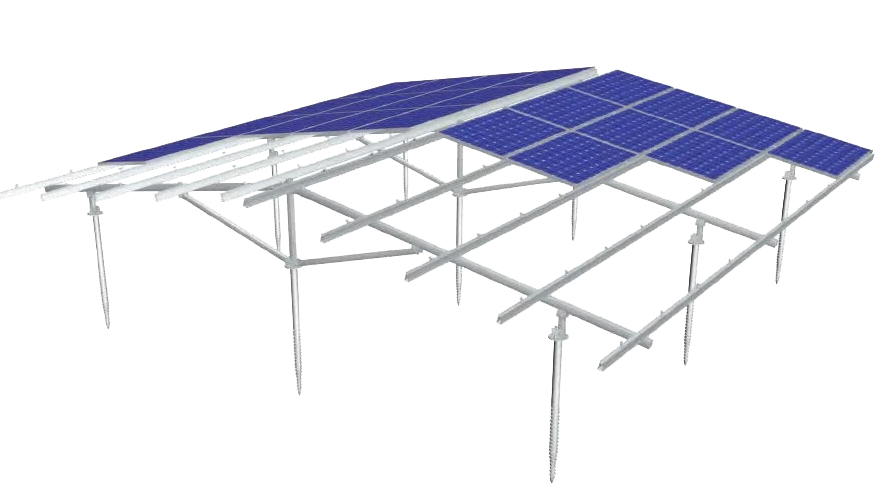

2) Commercial and industrial photovoltaic systems

At present, the mainstream of commercial and industrial light storage systems are ground installation and roof installation. In addition, solar carport systems are also becoming more and more widespread. Roof installation is mainly based on cement flat roof installation or color steel tile roof installation.

a) If it is installed on a cement flat roof, you can consider using the following flat roof mounting brackets:

MIBET cement flat roof photovoltaic mounting system

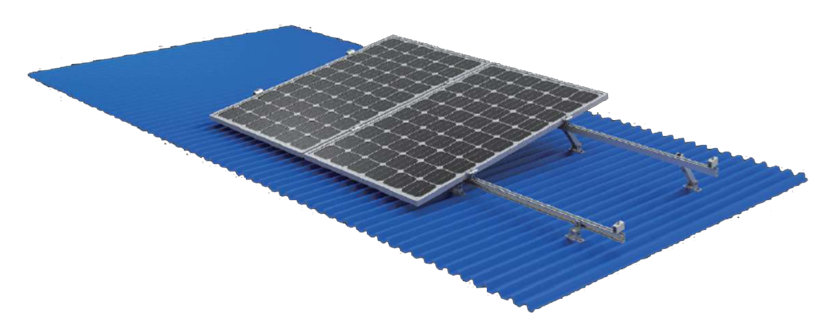

b) If the roof of an industrial factory is made of color steel tiles, you can consider using the following flat roof mounting brackets:

MIBET color steel roof photovoltaic mounting system

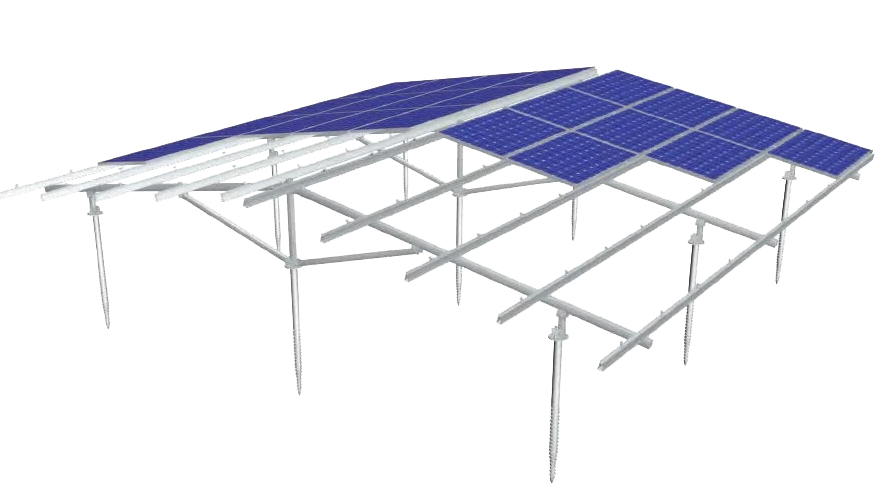

c) If it is installed on the ground, the following ground support system with concrete foundation and anchor bolts can be used.

MIBET MRac PGT4 ground support system for medium and large solar photovoltaic projects

3) Utility-scale PV plant

If it is a large-scale photovoltaic power station installed on the ground, the above-mentioned ground support system of concrete foundation and anchor bolts can also be used, or a solar tracking support system can be used.